It is now the middle of May but it is still too cool to fire up the machines in the rock lab. So we've been using the time to create more pieces for the shop. I had this piece of copper flashing that came from a collapsed and abandoned house and was well over 100 years old and decided it was time to put it to use and give it a second life. It would be reincarnated as cuff bracelets.

The first step was to cut out blanks.

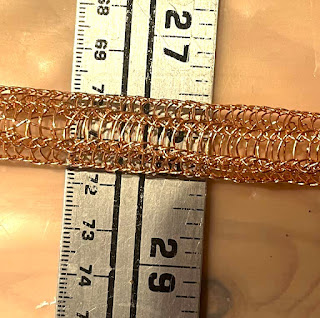

As you can see, they were pretty rough with some still having shingles and paint attached along with a lot of creases and dents. But this is what I treasure because it gives the final piece character. We decided to use two different techniques. The first was to clean up both sides and then pass the copper through our rolling mill with something (such as the plastic netting from an old onion bag) to create an impression.

The results were fantastic!

The second technique was to clean and polish the inside and then remove the verdigris, paint and some of the oxidation from the outer side. At that point we used several different "tools" to hammer from the inside to create raised points and creases on the rough side. Then, after a lot of filing and sanding, we had some amazing results.